Main Topics

Safety at All Levels

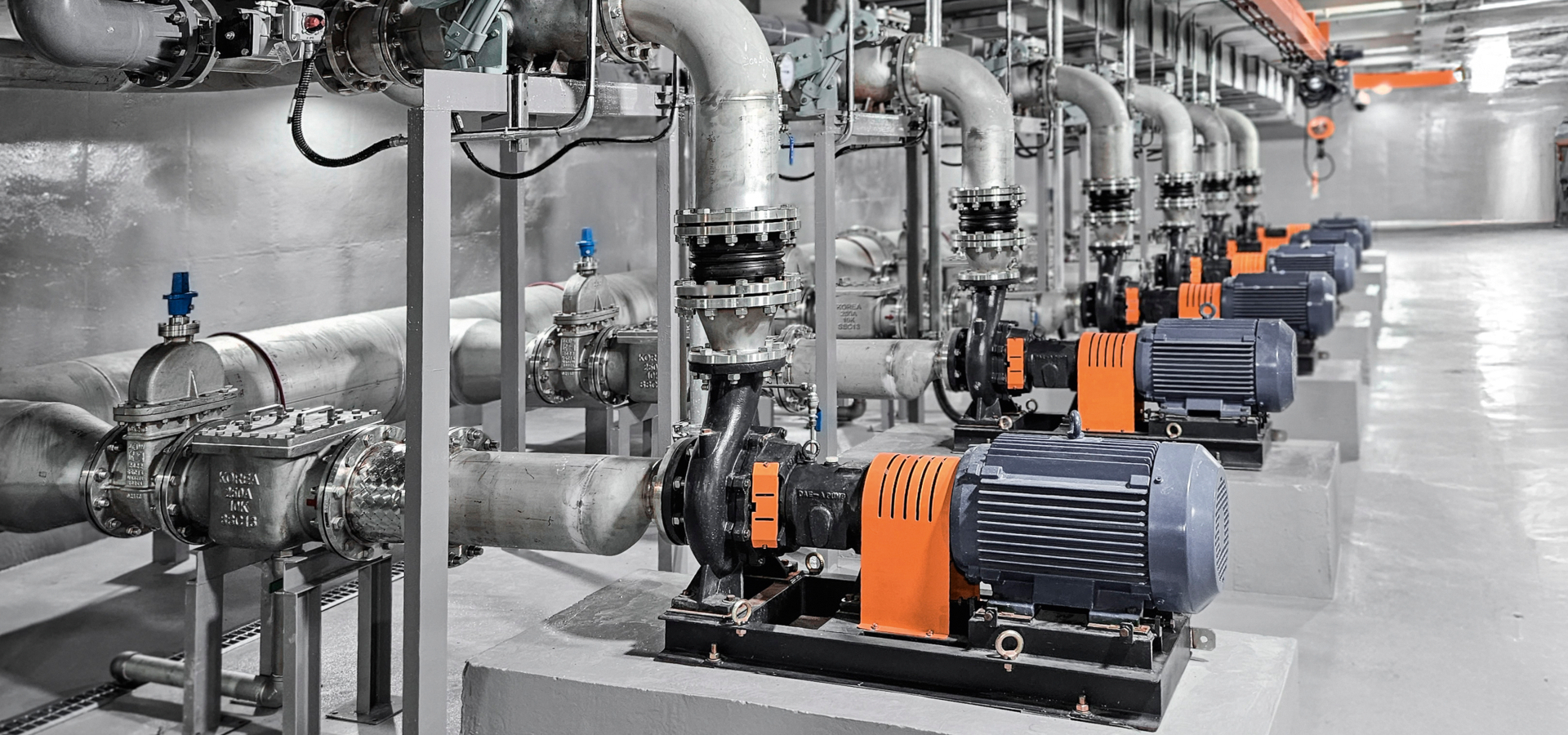

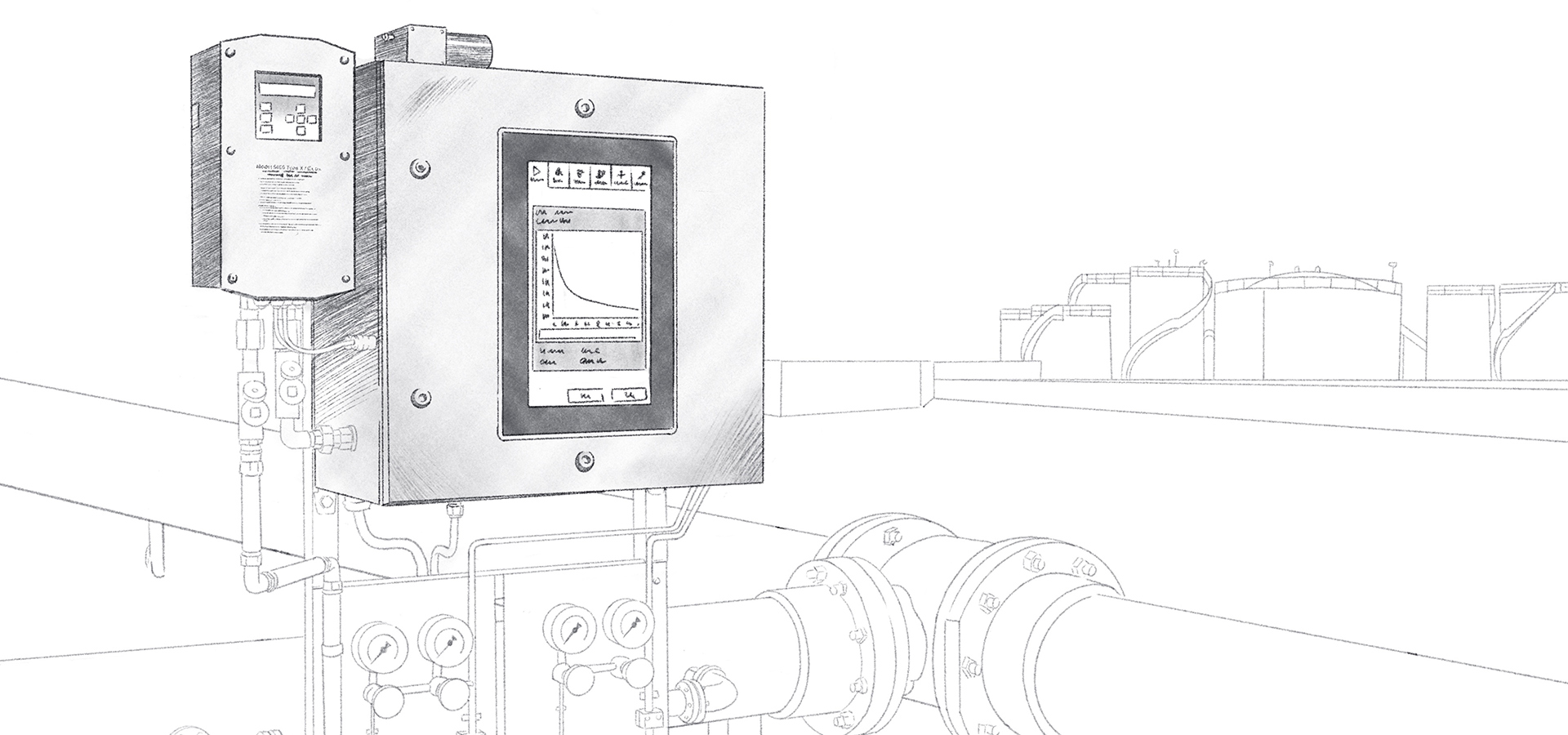

Your Content Goes Here Your Content Goes Here Precise alignment meets intrinsically safe technology: Easy-Laser uses the intrinsically safe Tab-Ex® 03 tablet for exact shaft alignment of rotating machines in Zone 1/21 and Div. 1 hazardous areas. In demanding industrial environments such as refineries, power plants, or chemical plants, one thing is particularly important: machines must operate reliably around the clock to ensure safe processes and avoid unplanned downtime. That is why more and more companies make use of predictive maintenance. The precise shaft alignment of rotating machines plays a crucial role in this. Even the slightest deviations in the tenth of a millimeter range can lead to excessive stress on bearings and couplings in the long term, which can result in costly damage and downtime. The XT550 alignment system from Swedish manufacturer Easy-Laser AB offers a solution to this problem: It enables high-precision alignment of shafts and was developed specifically for use in explosion-hazardous areas (Zone 1/21 and Div. 1). The key component of the mobile application is the intrinsically safe Tab-Ex 03 tablet from Pepperl+Fuchs. As one of the leading suppliers of laser alignment systems for rotating machines, Easy-Laser delivers around 1,500 systems annually to over 80 countries—including energy suppliers, steel mills, paper mills, and waterworks. There, the combination of precise laser technology and industrial tablets ensures that machines are optimally aligned, weak points are detected early, and unplanned downtime is avoided. Shaft Alignment Made Easy To ensure reliable plant operation over the long term, the rotating axes of two coupled machines, such as a motor and a pump, must be aligned as precisely as possible—and under real conditions in the field. This is where shaft alignment comes into play: Instead of working with feeler gauges or rulers, modern companies rely on laser-based alignment systems such as the XT550 from Easy-Laser. Two laser units precisely measure the position of the shafts in relation to each other, accommodating hard-to-reach couplings and confined spaces. The app developed by Easy-Laser on the Tab-Ex 03 series tablet from Pepperl+Fuchs guides maintenance personnel step by step through the process: from measurement and adjustment to final inspection. To accurately capture concentricity data, the shaft is rotated slowly, either manually or using an auxiliary motor. “Our systems ensure that rotating machines such as pumps or compressors remain precisely aligned at all times—both during commissioning and as part of regular servicing,” explains Peter Sandström, Head of Product Management at Easy-Laser. The shafts are checked at least once a year, and even weekly in particularly sensitive areas. The systems are easy to mount on machines and are protected against water and dust in accordance with IP66/67. “Important components are made of aluminum and stainless steel to deliver precise measurement results even under demanding ambient conditions,” adds Sandström. Around 10–15 % of Easy-Laser's customers require system solutions that are approved for explosion-hazardous areas up to Zone 1/21 according to ATEX and IECEx. In such environments, [...]

Erik Albrecht-Laatsch

Head of Engineering at Maximator HydrogenThe Ex e solutions from Pepperl+Fuchs are now used in almost all the modules we use to assemble our systems.

Lutz Liebers

Chief Operating Officer Process Automation at Pepperl+FuchsWith Ethernet-APL, users can finally make full use of the wealth of information that modern field devices and sensors record and make available. This changes everything for process plant operators!

Dr. Gunther Kegel

CEO Pepperl+FuchsOur Pepperl+Fuchs staff in Vietnam has already proven many times that they are willing to leave their comfort zone and contribute to the global success of Pepperl+Fuchs

Jan Schirweit

Sales Engineer at Pepperl+FuchsThe safety version of our PGV system has the advantage of multiple redundancy, making it highly resistant to interference and extremely reliable

Adrian Trabold

Director of Sales Excellence at NeoceptionWith the Neoception Digital Twin Infrastructure, we provide the appropriate infrastructure to break down existing data silos and make data centrally available, but above all, usable.

Thomas Schnepf

Sales Engineer for Process Automation at Pepperl+FuchsOverall, Ethernet-APL offers a powerful, digital solution for the integration of Ethernet networks in process plants that increases efficiency while ensuring the safety and performance of your systems.

Andreas Redekop

Project Manager at Vision Machine Technic Bildverarbeitungssysteme GmbHRobert Aasen Kverndalen

System and Solution Engineer, Factory AutomationWhatever the energy mix will look like in a completely decarbonized Norway: Pepperl+Fuchs is making an important contribution to this change with its products and solutions.