October 19, 2017

The Eye of the Donkey

A vehicle on Mecanum wheels can move in any direction, similar to a hovercraft. It provides flexibility and saves space—invaluable benefits in intralogistics. The PGV positioning system from Pepperl+Fuchs is used so that the miracles of movement from the company imetron always find their way.

“We named our industrial vehicle series ‘DONKEYmotion', after the longeared pack animal,” explains Project Manager Markus Mayr from imetron, the mechatronics specialists in Freiburg. “Like a donkey, it transports heavy loads with a towing load of several tons. At the same time, the ‘Donkey' can head in any direction, travel variable-radius curves, or turn on the spot and is thus particularly agile.” The secret to this unlimited mobility lies in the so-called Mecanum wheel, which has, in contrast to ordinary wheels, no end-to-end running surface. Rotating, barrel-shaped rollers are mounted on the rim at a 45 degree angle to the wheel axle. The direction of rotation and the rotation speed of each wheel is determined individually via a control panel, resulting in extremely high surface mobility.

“Unlike a forklift truck, for example, our Donkey does not need any space for maneuvering,” says Mayr. “In addition, a vehicle of corresponding size completely disappears under one euro pallet because these are loaded from above, and no part of the vehicle protrudes.” But it is not only the high mobility of the Mecanum wheels that makes the Donkey a sought-after addition to intralogistics: as an automated guided vehicle (AGV), it enables the automation of transport tasks. An optical read head from Pepperl+Fuchs ensures the required path tracking: the PGV100 is therefore formally known as the eye of the donkey.

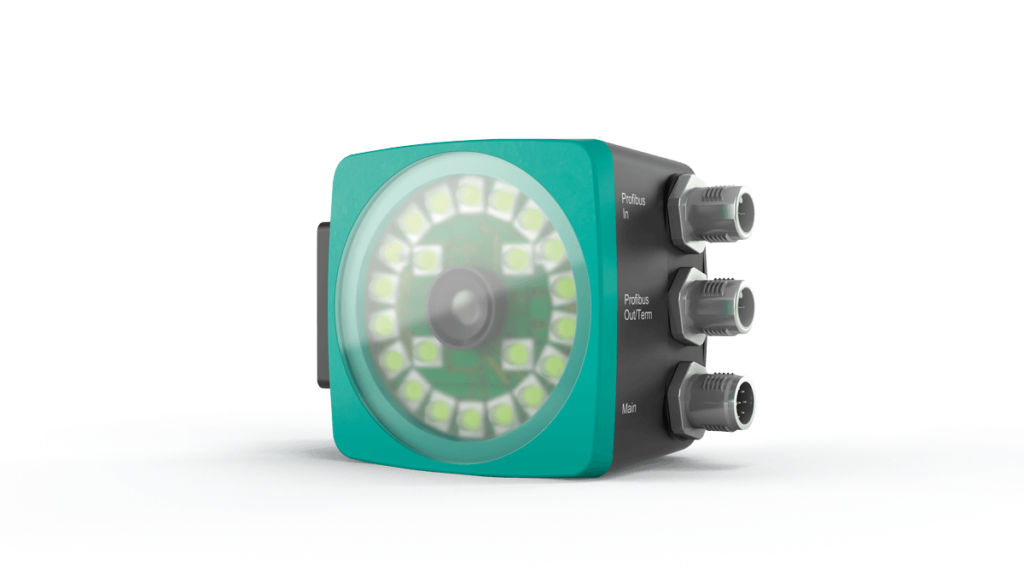

The PGV positioning system from Pepperl+Fuchs

Pioneering Technology

imetron uses this sensor, consisting of a 2-D camera and an LED light unit, in two ways. In one vehicle variant, it reads Data Matrix code tape on the ground so that the AGV follows the exact position of the tape at any point along a given path. The other variant of the Donkey requires only individual QR codes instead of the tape. Due to its high flexibility, the PGV100 covers this scenario just as successfully. “From the code, the sensor deduces the orientation of the vehicle in addition to precise position determination,” explains Mayr. “So the Donkey can drive independently from code to code. It is able to perform high-precision ‘parking' at a defined location, for example, to provide a heavy component for mounting. The PGV system ensures reliable path tracking and precise positioning, even on a highly reflective surface.” Thanks to its large reading window, damaged and dirty codes pose no problems for operation. In the construction of the AGV, the extremely space-saving design of the sensors also proved to be a real advantage.

“Connection to the vehicle control was also dealt with quickly thanks to the CANopen support of the PGV. Generally, mounting was extremely simple thanks to the plug-and-play nature of the sensor,” says Mayr, escribing the implementation. In addition, the PGV from Pepperl+Fuchs also impressed the experts at imetron with its robustness: the housing with IP67 degree of protection encases the electronics for signal processing, including fieldbus interfaces. Since its work is noncontact and is completed without moving parts, it is also maintenance-free and durable.

One Donkey for All Situations

imetron uses the sensor in all sizes of vehicle, from the compact model up to the heavy-duty Donkey, which carries up to 10 tons. The Donkeys are enjoying growing popularity, reports the project manager: “In addition to intralogistics, our customers come from many different areas. Our vehicles can, for example, replace a rotating stage in trade fair presentations or in the theater, act as a mobile mounting base, or serve as a tool changing truck. Like the Donkey´s movement, there are also no limits to its applications.”