November 15, 2017

The BlueBeam Group

BlueBeam, an innovative technology developed by Pepperl+Fuchs, offers a unique level of precision for rotary encoders: a blue LED combined with a high-performance scanning chip enables optimal use of light.

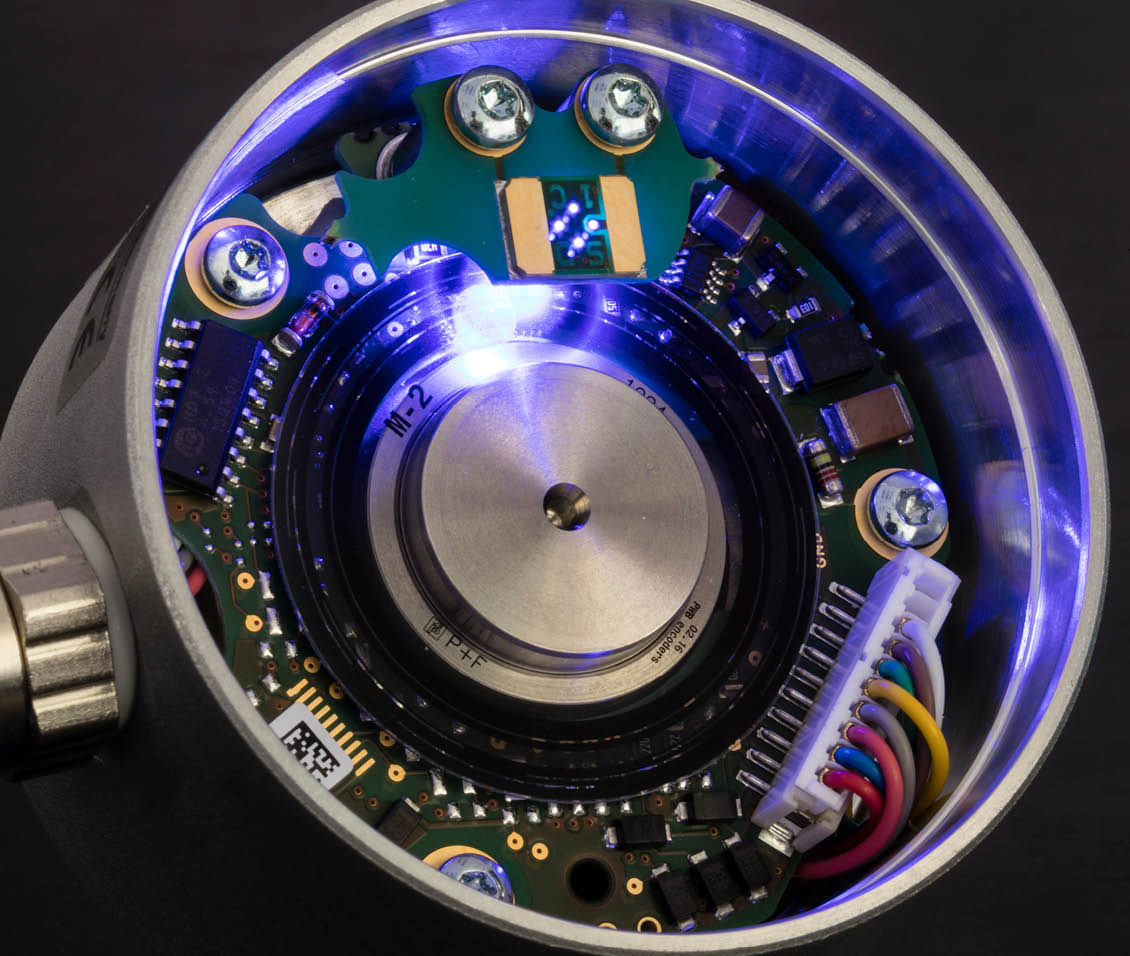

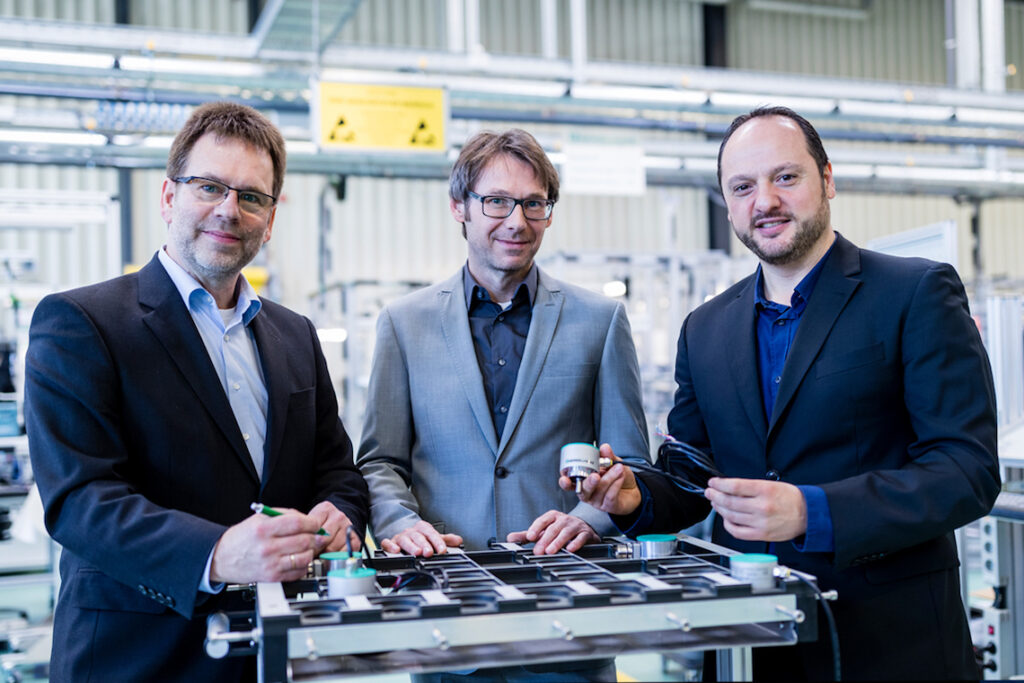

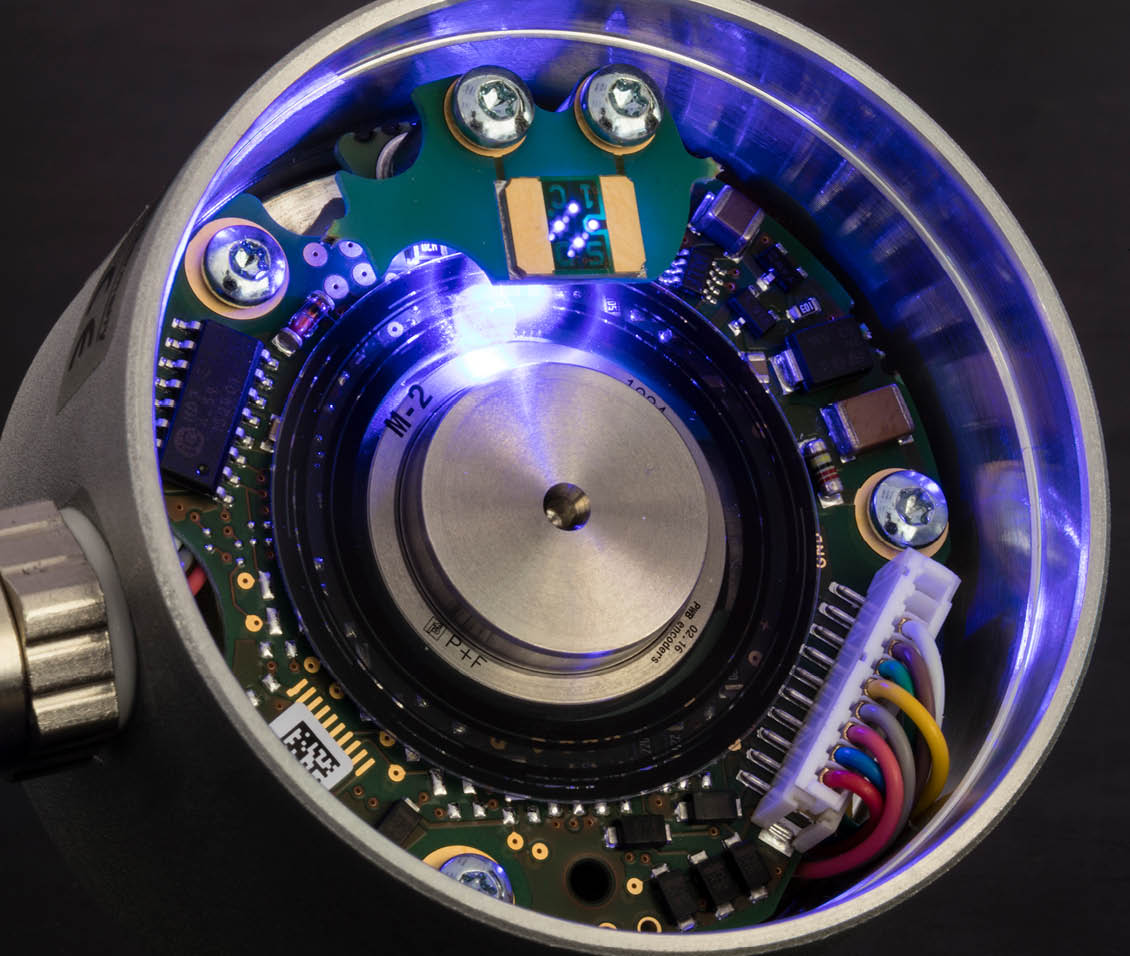

In the light of day, the cool blue glow in the metal interior of the opened-up device is hardly noticeable. Only under closer scrutiny can its origin be recognized: a focused light beam, only about the size of a pinhead. The considerable impact of this small blue point is, however, not to be dismissed: “Phase position A:B is far below 10%,” states Matthias Padelt, specifically quantifying the effect of the new “BlueBeam Technology.” As Managing Director, he is responsible for Pepperl+Fuchs Drehgeber GmbH. When you talk to Padelt and his team—Head of Innovation Management Thorsten Gippert and Head of Product Management Stefan Horvatic—it is easy to see how much lifeblood has flowed over the past few months into the ENI58IL series, the first to use BlueBeam technology. Horvatic points with a pen to the open incremental rotary encoder in front of him: “With this, we are setting a new standard in the market in terms of signal quality.”

Blue Trumps Red

The team achieved this by implementing a blue emitter LED and the corresponding receiver diodes. When used in conjunction with a powerful sensing chip, a significantly better utilization of light is possible than with commonly used infrared technology. But there were some hurdles that had to be cleared along the way.

Gippert recalls: “Selecting the optimal sensing chip, for example, was no easy task. We spent so much time researching until we found a model that met our requirements exactly.” The result of their effort is a higher resolution and greatly improved signal amplitude, as well as reduced jitter.

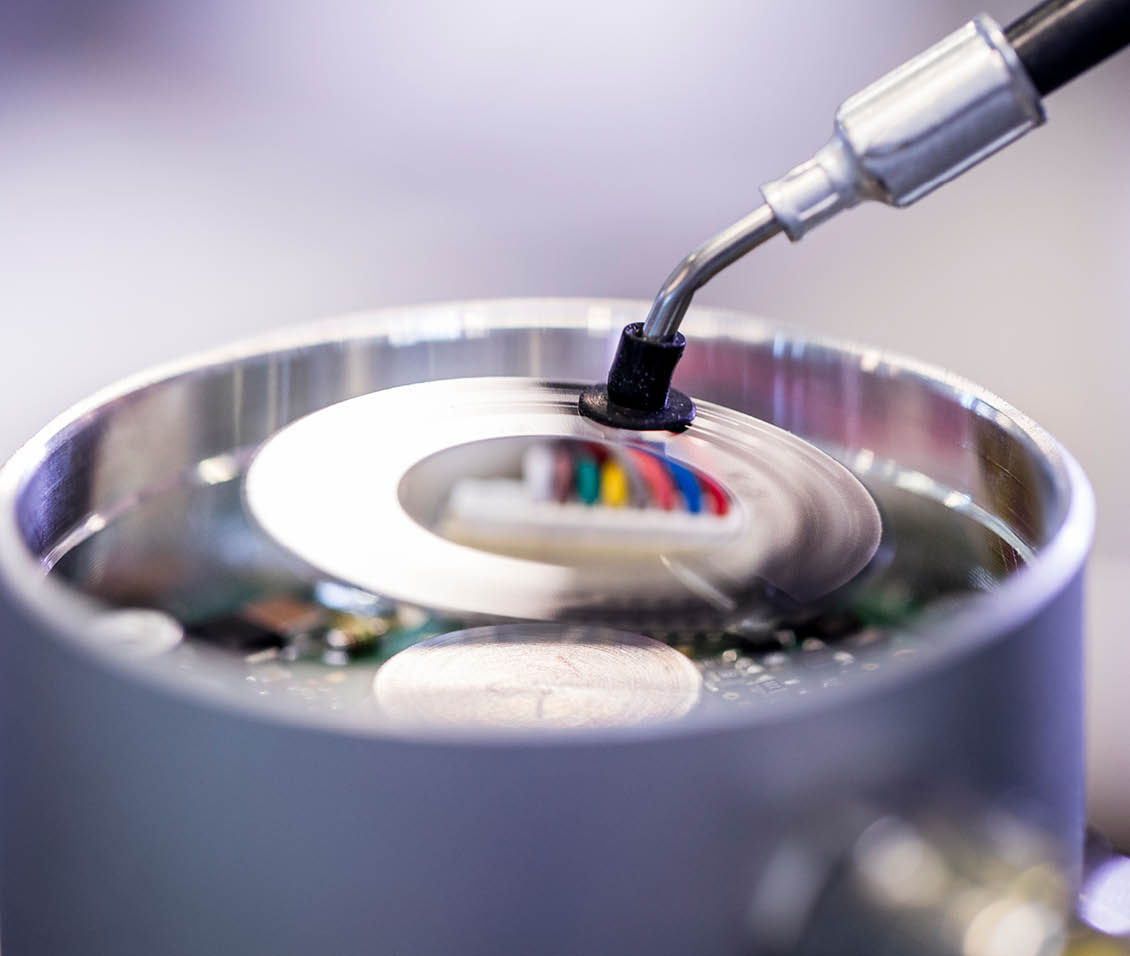

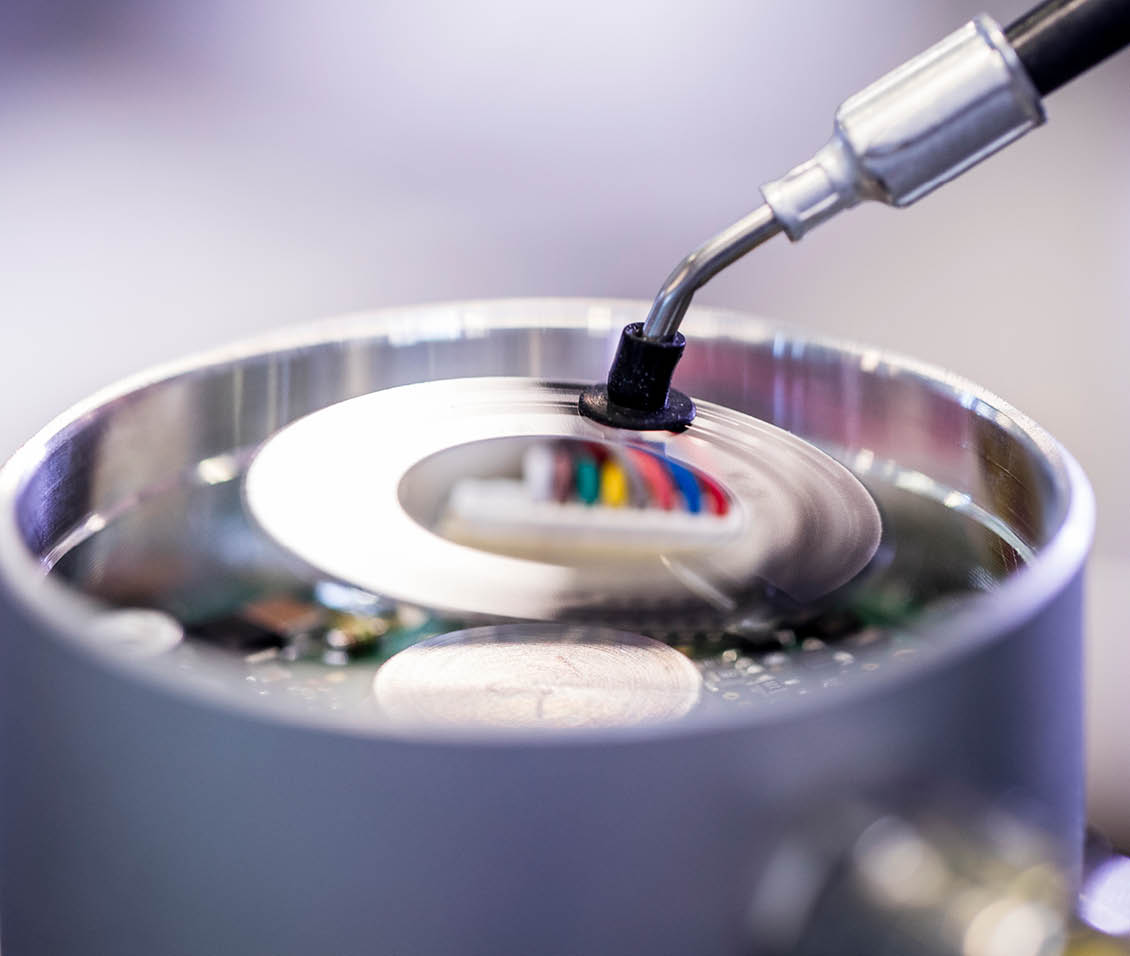

To further increase the extremely high measuring quality achieved with BlueBeam technology, the adjustment of the code disc was also refined in comparison to the standard procedure. “With the ENI58IL series, we´re moving in a new direction: here, the precise insertion of the disc is checked on a microscopic level during the manufacturing process. This step leads to improved absolute accuracy for applications in which even the smallest deviations cause a noticeable loss of performance—for example, when ensuring the perfect blade alignment on a wind turbine,” says Padelt, outlining the benefits.

Delicate Technology, Interlocked

In this context, it is not surprising that, during development, the team also worked intensively on the issues of longevity and process reliability. Along with the EMC protection circuit, this is supported by the robust construction with interlocked bearings that withstand high loads and prevent the ball bearing from being crushed. In addition to this powerful interlocking, the delicate BlueBeam technology has a positive impact on process reliability. “With BlueBeam, signals remain stable under high mechanical force such as shock or vibration, as high-frequency scanning offers more tolerance toward such interference,” explains Horvatic about the welcome side effect of the innovation.

Matthias Padelt, Managing Director Pepperl+Fuchs Drehgeber GmbH // Thorsten Gippert, Head of Innovation Management // Stefan Horvatic, Head of Product Management (left to right)

Sophistication Comes Standard

Is ENI58IL an exclusive series only for extremely demanding applications? Gippert forcefully denies this: “Quite the contrary! We provide the features needed for high-performance applications in a series of rotary encoders for the broad market. In doing so, we can handle applications with a sophisticated standard rotary encoder that previously could only be achieved using specialist devices. This is also reflected in the breadth of the available portfolio. We have almost all types of shafts, flanges, and connections.” Horvatic adds: “With ENI58IL, users receive innovation and reliability as standard worldwide, even in the smallest quantities.”

After the last steps of the product launch are taken, the question that remains for the three managers is: What´s next on the agenda? Padelt barely hesitates: “For now, we are eager to hear how this series of rotary encoders is received by our customers. At the same time, we are moving on to new challenges. This much is clear: BlueBeam technology will also be used in future product developments.”